One December evening, when the RPI team was closing the laboratory for Christmas, an unexpected visitor—a snowman—arrived with urgent news. A spill of MTBE and TBA at Santa’s workshop. Santa was concerned for the health of the reindeer, and the elves were panicking – we’ll have to halt Christmas they cried.

(Most people don’t know that Santa Clause depends on a deep groundwater aquifer for drinking, watering reindeer, and feeding his operations because surface water is not available in the arctic.)

The RPI Group quickly loaded the drill-sled, injection-sled, and the support sled and followed the snowman to the Arctic. Upon arrival, they found a grim scene: a contaminated aquifer. Wasting no time, they deployed BOS 200+® in four of Santa’s operational units. During the remedial design characterization (RDC), it was discovered that fifth operational units also contained TCE and chlorophenol, so the RPI Group installed CAT 100. The results were astounding. The contaminants were quickly and flawlessly degraded, the aquifer restored.

Santa said, “You’ve saved Christmas,” and commended the RPI Group for their swift action and innovative technology.

Returning to the RPI Laboratory, the team reflected on the impact of their work, proud to have again demonstrated the capabilities of BOS 200+ and CAT 100 in even the most challenging environment – the arctic, and the most pressing timetable – Christmas.

As much as I enjoy sharing an amusing story with you, the real heart of the RPI Group lies in its people—the dedicated individuals who are always ready to step up, excel in their roles, and embrace continuous learning.

As the year ends, Scott and I want to extend our deepest gratitude to the hardworking RPI Group team members who have installed our products at sites across the globe. Your efforts are the foundation of our success.

We also want to thank our clients for trusting us to assist with their environmental challenges. Your partnership inspires us to keep innovating and delivering our best.

Merry Christmas to all and a Happy New Year.

Kind Regards,

Ed Winner, PhD, Vice President

Remediation Products, Inc.

The fate of methyl tert-butyl ether (MTBE) and tributyl alcohol (TBA) from a gasoline released in soil and groundwater is influenced by several factors, including its chemical properties, environmental conditions, and the presence of microbial populations capable of degrading MTBE and TBA associated with gasoline or other compounds. RPI has not often been asked to report TBA, but we do have some data. We’ll concentrate on TBA because it is more difficult to biodegrade than MTBE and because California has a Health Notification at 12 μg/L (ppb).

The physical and chemical properties of oxygenates differ from gasoline. TBA and MTBE are relatively water-soluble compared to other gasoline components, i.e., 8.5 times and 23 times greater than benzene respectively. This makes these oxygenates more likely to dissolve into groundwater rather than attach to soil and aquifer materials. Once in groundwater, these oxygenates tend to form large dilute plumes that “outrun” the hydrocarbon components of gasoline.

BOS 200+ includes activated carbon (AC), a proprietary microbial population, electron acceptors such as sulfate and nitrate, and nutrients including yeast extract. It includes all the elements needed to biodegrade MTBE and TBA when the aquifer conditions are otherwise appropriate, e.g., pH.

Activated carbon is modestly effective in containing TBA due to AC’s relatively weak adsorption capacity for this compound. The adsorption capacity of AC for TBA is typically around 7 mg TBA per gram AC for a TBA concentration from an aqueous phase of 30 ppm. Activated carbon has a higher adsorption capacity for MTBE at 30 mg per gram of AC also from an aqueous phase of 30 ppm. The adsorption capacity depends on the concentration of the oxygenate, the specific type of AC, and the conditions of the adsorption process, such as temperature and solution concentration. Oxygenates have a relatively weak interaction with AC when compared to the hydrocarbons in gasoline. Although AC may slow the partitioning of TBA into groundwater (Shih, 2003), AC does not significantly prevent migration. On the other hand, AC does restrain hydrocarbon dispersion, and its presence may accentuate the separation of oxygenates from gasoline by restraining the hydrocarbons. It has been noted that when TBA is disassociated from gasoline in aquatic sediments, TBA degrades rapidly to CH4 and CO2 (Finneran, 2001).

TBA can often be found in groundwater due to the biodegradation of MTBE, a previously used gasoline additive. While MTBE biodegrades when conditions are appropriate, the resulting degradation product TBA often accumulates. Biodegradation is a critical process for the remediation of oxygenates under both aerobic (Bradley, 2002) and anaerobic conditions, although the degradation rate depends on site-specific factors. Under aerobic conditions the degradation of TBA has been associated with monooxygenase enzymes present in the microbial population. In anaerobic conditions, electron acceptors like nitrate, sulfate, or reduced iron are required. For example, mineralization of MTBE without accumulation of TBA has been shown under denitrifying conditions (Bradley, 2002). Fe(III) reducing conditions are also associated with anaerobic degradation of TBA (Laskin 2007) (van der Waals 2018). BOS 200+ includes sulfate and nitrate as potential electron acceptors.

Microbial populations that degrade TBA often include Xanthomonas, Pseudomonas, Rhodococcus, and Bradyrhizobium species. Additionally, Hydrogenophaga a common soil bacterium, often observed in hydrocarbon-impacted soils (D’Ugo, 2021), is capable of mineralizing TBA (Gyula 2013) particularly when stimulated by additives such as BOS 200+® (Internal observations). These are facultative anaerobes for which H2 and thiosulfate oxidation energy production have been identified. Hydrogenophaga species have demonstrated the ability to use root metabolites like vanillate, ferulate, and syringate (van der Waals, 2018) and yeast as cometabolic substrates (Hatzinger, 2001; Bradley, 2006). Yeast extract may also contribute through the biotic production of H2 (Bradley P. C., 2006). BOS 200+ includes Xanthomonas, Pseudomonas, Rhodococcus, and Bradyrhizobium species. BOS 200+ also includes yeast extract.

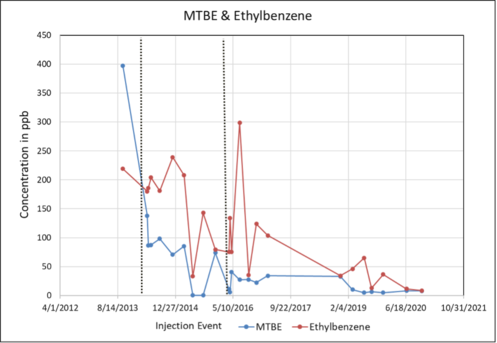

Site one was a gasoline release site injected with BOS 200+ in April of 2014 and again in April of 2016. MTBE data was consistently collected. The decrease in MTBE was 50-fold over about 70 months. Ethylbenzene was graphed with the MTBE because it was of the same magnitude and illustrates the pattern of decrease of the BTEX compounds. See Figure 1. Multiple injections were planned to address LNAPL and benzene concentrations in the ppm range as well as the client’s changing the goal from the elimination of LNAPL to site closure.

Site two was a gasoline release site for which we have 8 months of data prior to BOS 200+ injection. While it is difficult to see due to the scaling of the y-axis, the final concentrations of both MTBE and TBA were below 10 μg/L by 10 months after the BOS 200+ injection.

The third site was not a gasoline release site. This site had over 20 contaminants such as methylene chloride, trichlorethylene, chlorobenzene, benzene, and naphthalene. While TBA was present, MTBE was not present on this site. We’ll focus on TBA. The site was injected with CAT 100 in November of 2016. In 6 months, TBA was non-detect at 2 mg/L. While not the topic of this article, CAT 100 performed well on the other contaminants as well.

CAT 100 shares some similarities with BOS 200+ but the activated carbon used in CAT 100 is a single substance having elemental iron integrated into the molecular structure. It also includes a larger population of microbes.

MTBE and TBA are more water soluble than the petroleum components of gasoline; thus, degradation of is often identified away from the core mass of the gasoline at the leading edge of the plume. Biodegradation may stall without sufficient cometabolic substrates or carbon sources, such as those provided by yeast extract and other augmentations to the activated carbon in BOS 200+ or CAT 100. Contaminants like TBA with complex degradation mechanisms may experience incomplete degradation if essential factors, such as electron acceptors or suitable microbial populations, are absent.

The fate of oxygenates in the environment is shaped by their unique chemical properties, biodegradation potential, and environmental conditions. While MTBE and TBA are biodegradable under diverse conditions, their degradation often requires specific microbial populations, electron acceptors, and supplementary materials. BOS 200+® addresses these requirements and satisfies these needs. In one case for which we have data, CAT 100 also degraded TBA within a “soup” of chlorinated and BTEX compounds.