18 Sep Quantitative High-Resolution Site Characterization (qHRSC) and Achieving Efficiency in Remediation

During the week of August 21st, I participated in a treatment trains webinar hosted by NEIWPCC. In his presentation, my colleague Tom Fox (Colorado, OPS) cited 21 as the number of hydrocarbon remedy categories. Wow, that’s overwhelming! While exceptions may exist, each of the 21 remedies should work when employed by knowledgeable and experienced individuals in the appropriate geological setting supported by sufficient site characterization. The dilemma is knowing which remedy is efficient.

As a remedy producer, I want you to use RPI’s BOS and CAT product lines! But that’s not really the answer to the question, and the readers of this Newsletter know that no one product or product class is the efficient remedy for all sites.

To understand a complex question, you must get to the bone. I have observed three indispensable foundational elements of an efficient remediation effort. One, find the three-dimensional location(s) of the contamination, and two, understand the nature of the soil and aquifer material (SAM) that holds most of the contamination. (Why are there so many geologists in our industry? It is because of the centrality of these first two elements.) Three is often overlooked—you must be able to state a quantitative value for the mass of contamination and the error on that estimate.

Regardless of the remedy employed, the only way to maintain efficiency is by tracking the mass removed or degraded by the dollars expended per time. You can then apply that information to the remaining contaminant mass to determine when a remedy is no longer efficient (diminishing returns) or the site is ready for reuse. To know the contaminant mass and the error on that estimate is to have a standard to measure efficiency.

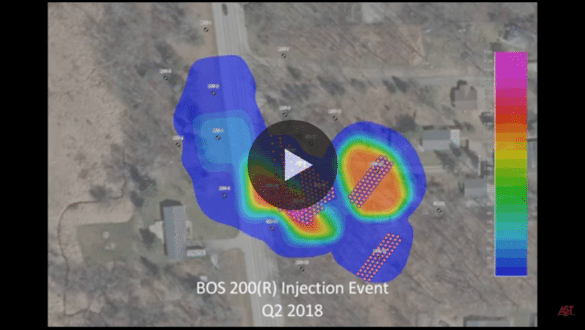

Field tools such as MIP, OIP, and UVOST® are exceedingly valuable in helping find the three-dimensional location(s) of the contamination. HPT and other well-known tools and techniques allow us to understand the SAM stratification. For simplicity’s sake, we will set bedrock characterization aside; although the principles are the same, the tools require their own list. Nevertheless, chemical characterization tools such as MIP are not quantitative and do not support a quantitative estimate of the contaminated mass. For this reason, a quantitative high-resolution site characterization (qHRSC) based upon multiple samples of the SAM analyzed in a laboratory by GC/MS is integral to an RPI project.

To support the remediation community, the RPI laboratory in Golden, Colorado, analyzes both SAM and groundwater samples for free!

We do not just analyze samples for clients committed to using RPI products. You can arrange with the RPI Laboratory to have your samples analyzed. Then, you can build out that third indispensable element in remediation efficiency—state the mass of contamination and the error on that estimate.

The RPI Laboratory and the RDC process represent our commitment to designs without data gaps, efficiency remedies, and results that exceed expectations. Let us know if we can help.

If you liked this content check out our previous newsletter sends here.

Featured Case Studies:

High Resolution Remedial Design and Ejlskov’s ESM Modeling Tool

Date: Wednesday, September 27th, 2023

Time: 10:00 AM MST/ 12:00 PM EST

Why Injected Permeable Reactive Barriers Fail: Avoiding Design and Installation Mistakes

Date: Wednesday, October 11th, 2023

Time: 10:00 AM MST/ 12:00 PM EST

No Comments